- Products

- Industries

AUTOMOTIVE

ROAD CONSTRUCTION

AGRICULTURE

FOOD AND BEVERAGES

TRANSPORT & LOGISTICS

AIRCONDITIONING (FANS & COMPRESSORS)

- Contact Us

- RESOURCES

- Blog

OCM chains are used in various equipment. The company was founded in 1947 to manufacture chains. Since then OCM has been engaged in the manufacture of roller chains, conveyors and sprockets. UMS Australia Pty Ltd is the authorised distributor of OCM Chains in Australia. We stock and supply OCM Conveyor chains like Standard Conveyor Chain (R-Roller, F-Roller and S (M) Roller), Conveyor Chain with Attachments (Type A-2, Type K-2, Type SA-2, Type SK-2, Type G-2, Type G-4), Flow Conveyor Chain (Type B, Type U, Type K, Type KL), Deep Link Plate Conveyor Chain, Outboard Conveyor Chain, Apron Conveyor Chain, Curve (Sidebow) Conveyor Chain – Type CL, Type SL.

CONSTRUCTION OF CONVEYOR CHAIN – There are many types of chains for conveyor applications, but steel conveyor chains are popular and widely used. OCM FM and FE type conveyor chains are superior to other types in strength, wear- resistance and the characteristics that changes in material and attachment are readily made according to an application.

Please contact us for all yur conveyor chain needs.

Features of OCM Roller Chains

- OCM JAPANESE MANUFACTURED COMPETES WITH THE WORLDS BEST ROLLER CHAINS!

- Re-Punched Link Holes OCM's repunching process removes the taper of hole. Both sides of the hole are parallel, better bearing between pins and holes. This process increases fatigue strength

- AVERAGE TENSILE STRENGTH: 17,367LBS. Shot-Peening Rollers and link plates are shot peened to increase fatigue strength

- Cylindrical Roundness - Solid Bushings The advantage of solid bush, cylindrical roundness, makes for a large bearing area and oil port as an oil reservoir, improves the chain wear resistance and minimize chain elongation.

- Preloading OCM roller chain is preloaded automatically after assembly to minimize initial elongation

- Oil Port oriented + Solid Bush: These holes, located on the inner side of the bushings away from bearing area, function as a reservoir for extra lubricant. This feature reduces chain wear and extend the chain’s operating life.

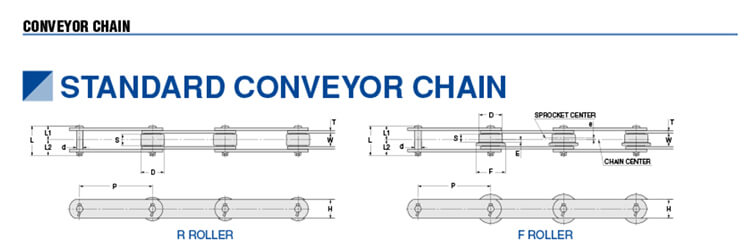

Standard Conveyor Chain

These chains are assembled from precisely-fitted links, bushes and pins, each made from carbon steel or hardened steel, to give accurate dimensions. Rollers are available in R, F or S roller types to suit different applications.

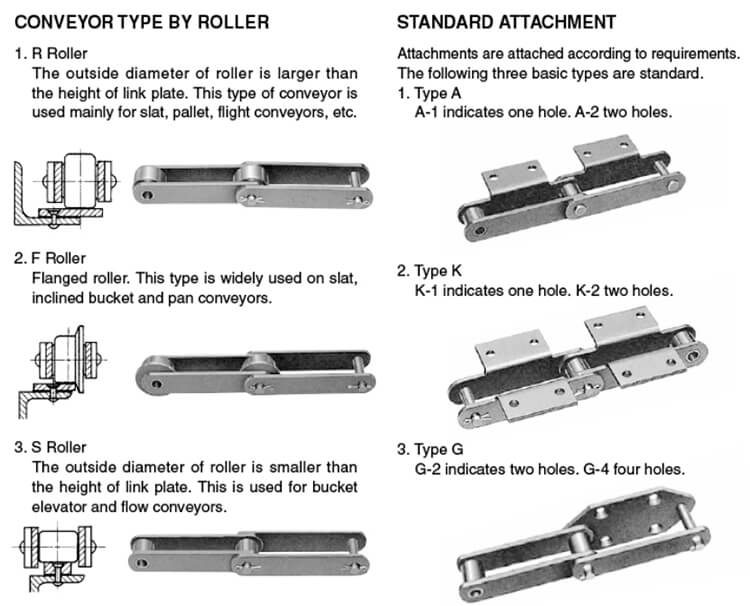

R Roller The outside diameter of roller is larger than the height of link plate. This type of conveyor is used mainly for slat, pallet, flight conveyors, etc.

F Roller Flanged roller. This type is widely used on slat, inclined bucket and pan conveyors.

S Roller The outside diameter of roller is smaller than the height of link plate.

This is used for bucket elevator and flow conveyors.

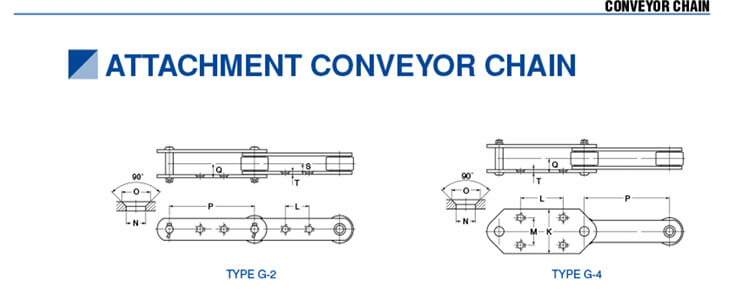

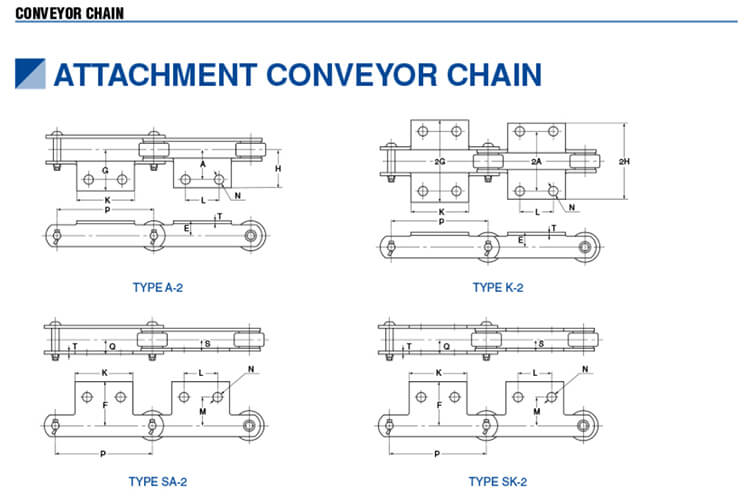

Conveyor Chain with Attachments

Conveyor chains with attachments are standard conveyor chains mounted with various attachments as required. Attachments are attached according to requirements. The following three basic types are standard attachments used with the conveyor chains.

- Type A where A-1 indicates one hole and A-2 means two holes.

- Type K where K-1 indicates one hole and K-2 means two holes.

- Type G where G-2 indicates two holes and G-4 means four holes

These chains use straight link plates. They are divided into the large roller series and the small roller series, according to the outer diameter of the rollers used.

These chains are double pitch roller chains for conveyor use, with various attachments added as necessary.

Double pitch stainless steel roller chains for conveyor use are made from 300-class stainless steel.

They can be used in acid, alkaline or wet conditions, hot and cold conditions, and in other special atmospheres which require temperature and corrosion resistance.

Deep Link Plate Conveyor Chain

These chains are based on standard conveyor chains, but the link plate height is increased to allow conveyance of heavier objects, and an R type roller is used for reduced frictional resistance. They are mainly used in applications such as thick plate and steel section conveyance in steel works, and container assembly and movement lines.

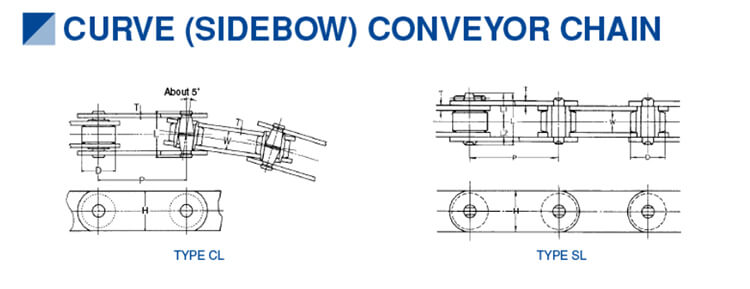

Curve (Sidebow) Conveyor Chain

These chains are generally used as conveyor or drag chains in applications that require curved tracks. The chains may have different bow radii. As a rule, the pin diameter of these chains is smaller, but conical pins or bi-conical bushes are also possible. This special pin shape allows curves to be negotiated in many applications that involve a variety of curve radii. Specially designed pin links allow increased clearance between pins and bushings and between the roller link and pin link plates. This feature gives the chain freedom to slightly twist or curve on a horizontal plane. The increased internal clearances within this chain allow it to side flex making it ideal for curved conveyors. Sidebow chain uses standard roller links and special pin links and runs on standard sprockets. Depending on the application, side bow chains can be supplied with special lubricants or special coatings, or fitted with bent attachments, flat plastic conveyor plates or extended pins.

APRON CONVEYOR CHAIN

This OCM apron conveyor is ideal for conveying bulk material such as chips made by machine tools.

Main features

- Excellent for conveying small bulk material. Each apron plate is closely connected by hinges.

- Even tiny particle such as sand are easily conveyed.

- Side chains are OCM standard conveyor chain. OCM standard sprocket can be used.

- Specifications can be changed according to applications.

- Aprons are partitioned with plates, and different materials without mixing can be conveyed.

- For sharp inclined conveyor, stop plates are available. The stop plate can be installed at any desired pitch.

- For drying and freezing parts or material, small holed aprons are available.

- Stainless apron is available.

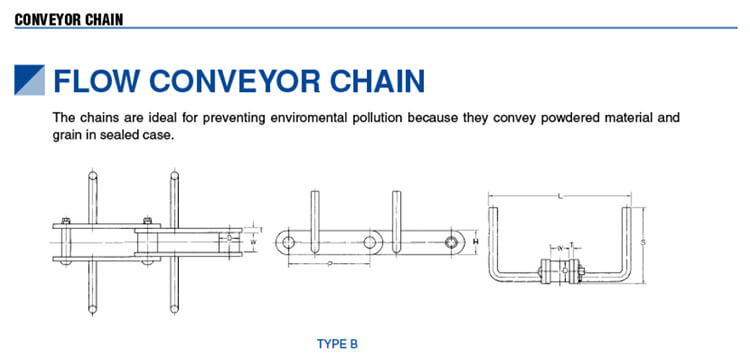

FLOW CONVEYOR CHAIN

The chains are ideal for preventing enviromental pollution because they convey powdered material and grain in sealed case.

OUTBOARD CONVEYOR CHAIN

Base chain is FM type S roller conveyor chain with flange outboard roller. When ordering, please specify the spacing of outboard roller

Industries / Applications

All Giga Torque polyurethane belts are abrasion-resistant, provide thermoplastic flexibility and are long-lasting, energy efficient belts suitable for all heavy-duty industries and applications.

Heavy Duty Truck

Bus

Agricultural

Harvestor

Jeeps

Snowmobile