- Products

- Industries

AUTOMOTIVE

ROAD CONSTRUCTION

AGRICULTURE

FOOD AND BEVERAGES

TRANSPORT & LOGISTICS

AIRCONDITIONING (FANS & COMPRESSORS)

- Contact Us

- RESOURCES

- Blog

OCM chains are used in various equipment. The company was founded in 1947 to manufacture chains. Since then OCM has been engaged in the manufacture of roller chains, conveyors and sprockets. OCM is, therefore, in a position to meet customer’ requirements with broad experience and endless research. For over 58 years OCM’s effort has been to solve the problems of industry. OCM S10 the world’s smallest chain and OSB Series OCM has first manufactured indicate its ability. OCM’s dedication is to provide products that help solve the problems of industry in the world.

Features

Re-Punched Link Holes

OCM’s repunching process removes the taper of hole. Both sides of the hole are parallel, better bearing between pins and holes. This process increases fatigue strength.

Shot-Peening

Rollers and link plates are shot peened to increase fatigue strength.

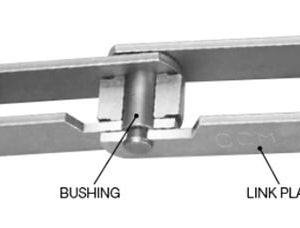

Oil Port oriented + Solid Bush

These holes, located on the inner side of the bushings away from bearing area, function as a reservoir for extra lubricant. This feature reduces chain wear and extend the chain’s operating life.

Cylindrical roundness of Solid Bush

The advantage of solid bush, cylindrical roundness, making a large bearing area and oil port as an oil reservoir, improves the chain wear resistance and minimize an initial chain elongation.

Preloading

OCM roller chain is preloaded automatically after assembly to minimize initial elongation.

CONSTRUCTION OF ROLLER CHAIN

Roller chain is made up of roller links and pin links. Roller link consists of two bushings press-fitted into roller link plates with two free rotating rollers over the bushings. Pin link consists of two pin link plates into which two pins are press-fitted. There are two types of pins — Rivet and cotter types.

ROLLER CHAIN CONNECTION CONNECTING LINKS

- Spring clip type This is standard for all single and multiple strand ANSI standard chain, 80 and below and British standard chain, 16B and below.

- Cotter type This is standard for all single and multiple strand ANSI 100 and above, and British standard 20B and above.

- Offset Link An offset link is a combination of a roller link and a pin link. This link is used where the chain length is an odd number of pitches. It is recommended not to use an offset link whenever possible.

- Two Pitch Offset Link The unit consists of one offset and one roller link. Pins are press fitted into the link plates and the unit is more suitable for heavy impact load and high speed driving than one pitch offset link.

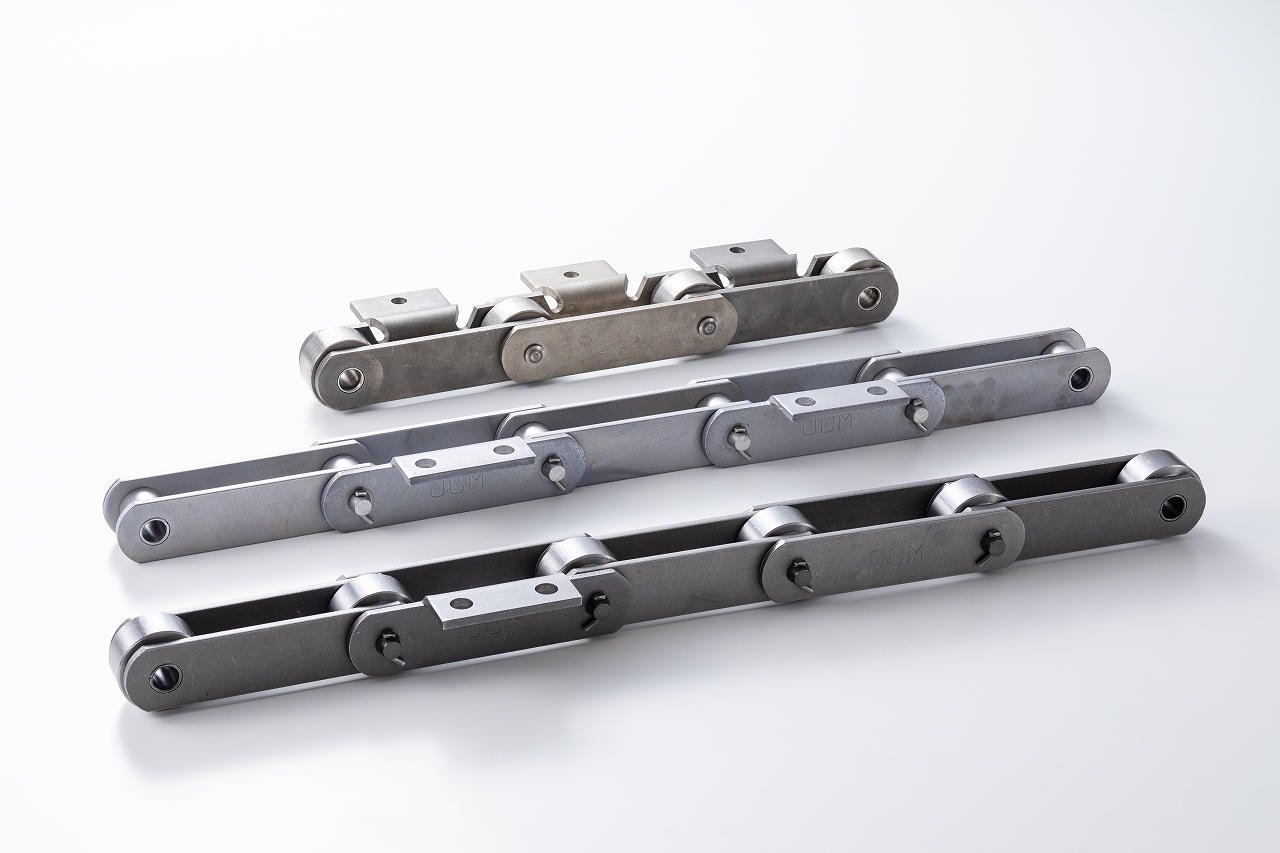

OSB SERIES ROLLER CHAIN

OCM introduces, OSB Series, oil port oriented solid bush roller chain with solid roller. Over 30 years’ experience of manufacturing oil port roller chain made this possible. It incorporates the advantage of solid bush, cylindrical roundness, making a large bearing area and oil port as oil reservoir. The large bearing area and oil port, acting as an oil reservoir, improve the wear resistance and prolong the chain life by 30% as compared with solid bush chain without oil port under no lubricating condition.

OCM SELUBE CHAIN

OCM SELUBE chains provide excellent wear life without lubrication as much as 8 to 30 times better than standard roller chain.

SELUBE chain is made up of sintered metal bushings impregnated with high quality oil and plated pins. As SELUBE chain does not require lubrication, it is suitable for applications where lubrication is not possible or practical. All major dimensions are the same as standard roller chain. SELUBE chain can immediately replace standard ANSI roller chain. The operating temperature should be within a range of -10°C (14°F) to 150°C (300°F). The chain operating speed should be kept below 150m (490feet) per minute. SEB type SELUBE chain has the same maximum allowable load quidelines as standard roller chain. This chain has shouldered sintered bushings with heavy link plates. As compared with SER type, the bushings of SEB are larger and more oil impregnated. SEB type can last longer than SER without lubrication. This chain can operate on standard sprockets. SER type SELUBE chain has the same maximum allowable load guidelines as standard roller chain. This chain has straight bushings with rollers and heavy roller link plates. SER type chain offers smooth engagement with the sprocket. This chain can operate on standard sprockets. SELUBE small conveyor chain has straight sintered bushings impregnated with high quality oil and strong rollers. This chain can replace standard conveyor chain and operate on standard sprockets. The strength of SELUBE small conveyor is lower than that of SER, SEB and standard steel chain.

Industries / Applications

A wide range of machinery from light duty power transmission for OA and household electric appliances to heavy duty power transmission such as printing machines, machine tools and crushers

Industrial Power Transmission

Agricultural

Automotive

Pipeline Protection for Oil & Gas, Waterworks

Food Industry Conveyor Belts

Paver Belt