- Products

- Industries

AUTOMOTIVE

ROAD CONSTRUCTION

AGRICULTURE

FOOD AND BEVERAGES

TRANSPORT & LOGISTICS

AIRCONDITIONING (FANS & COMPRESSORS)

- Contact Us

- RESOURCES

- Blog

Shaft Coupling is a machine element that connect shafts. UMS offers an extensive line-up of couplings to meet diversified needs — from general applications to high precision servo motor applications.

Jaw Coupling is the most common type of coupling available in the market today. UMS Transmissions stocks a wide range of Jaw coupling in many different shapes, sizes and materials.

Loading...

Shaft Coupling

Shaft coupling is a machine element that connect shafts. UMS offers an extensive line-up of couplings to meet diversified needs — from general applications to high precision servo motor applications.

- Chain Couplings

- Disk Couplings

- Beam / Bellows Couplings

- Elastomer Couplings

- Power Rigid Couplings

HRC Coupling

This is the most common type of coupling available in the market today. UMS Transmissions stocks a wide range of Jaw coupling in many different shapes, sizes and materials. These couplings require no lubrication and provide highly reliable service for light, medium and heavy-duty electrical motor and internal combustion power transmission applications. All couplings supplied by UMS Transmissions are reliable and durable across a broad range of industries and applications. The Jaw Couplings can be incorporated into existing designs thus giving your plant a reduced downtime. The Jaw Coupling is highly resilient and can work in environments contaminated with oil, dirt, sand, moisture and grease.

Chain Couplings

This is the most common type of coupling available in the market today. UMS Transmissions stocks a wide range of Jaw coupling in many different shapes, sizes and materials. These couplings require no lubrication and provide highly reliable service for light, medium and heavy-duty electrical motor and internal combustion power transmission applications. All couplings supplied by UMS Transmissions are reliable and durable across a broad range of industries and applications. The Jaw Couplings can be incorporated into existing designs thus giving your plant a reduced downtime. The Jaw Coupling is highly resilient and can work in environments contaminated with oil, dirt, sand, moisture and grease.

JAW COUPLING

This is the most common type of coupling available in the market today. UMS Transmissions stocks a wide range of Jaw coupling in many different shapes, sizes and materials. These couplings require no lubrication and provide highly reliable service for light, medium and heavy-duty electrical motor and internal combustion power transmission applications. All couplings supplied by UMS Transmissions are reliable and durable across a broad range of industries and applications. The Jaw Couplings can be incorporated into existing designs thus giving your plant a reduced downtime. The Jaw Coupling is highly resilient and can work in environments contaminated with oil, dirt, sand, moisture and grease.

The rubber insert is designed to absorb shock loading and does not allow for any metal on metal contact. UMS Transmissions stocks both the Spider Elements (rubber, polyurethane & Hytrel) as well as the Wrap Element Kits in a variety of pre-bored and keyed sizes.

Types of Jaw Couplings

- L035 to L225 range available in Pilot Bore and large range of Bored and Keyed

- L100 to L225 range available in Taper Bore (F and H flanges)

- L095 to L225 range available with Spacer Kits of 100mm and 140mm

- Snap Wrap elements

- Polyurethane elements

Features

- Fail-safe - will still perform if elastomer fails.

- No metal to metal contact.

- Resistant to oil, dirt, sand, moisture and grease.

Benefits

- The coupling requires little or no maintenance with an easy and quick installation.

- Reduction in operation cost,

- Longer life

- No need for laser alignment

When equipment from overseas is used in Australia, UMS Transmissions can also provide the replacement flexible couplings and elastomers.

Industries / Applications

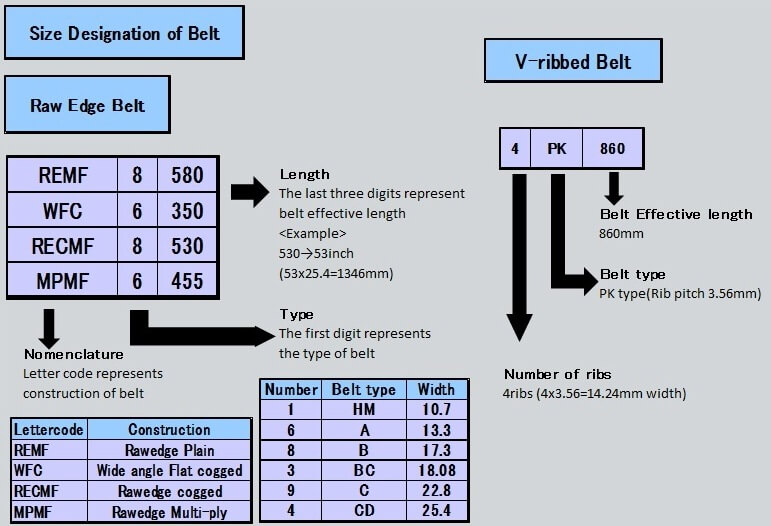

All Giga Torque polyurethane belts are abrasion-resistant, provide thermoplastic flexibility and are long-lasting, energy efficient belts suitable for all heavy-duty industries and applications.

Heavy Duty Truck

Bus

Agricultural

Harvestor

Jeeps

Snowmobile