- Products

- Industries

AUTOMOTIVE

ROAD CONSTRUCTION

AGRICULTURE

FOOD AND BEVERAGES

TRANSPORT & LOGISTICS

AIRCONDITIONING (FANS & COMPRESSORS)

- Contact Us

- RESOURCES

- Blog

Mitsuboshi OHC Timing belt is Belt used for Cam Shaft Drive of Automotive Engine. The opening and closing of the engine intake exhaust valve is used by the cam shaft and drive belt to synchronize transmission. The engine’s timing belt drives the camshaft (s) (“top end”) from the rotation of the crankshaft (“bottom end”). The belt keeps the piston and valves in “time” during operation. Timing belts also known as Synchronous Power Transmission belts have ‘teeth’ or ‘notches’ inside which fit into a matching toothed pulley. This ensures no slippage, meaning the belt runs at a constant speed.

Serious internal engine damage can occur when the piston and valves come into contact with each other “out-of-time” caused by a damaged belt etc. In the worst case, the engine assembly will need to be replaced. Failure to replace the timing belt at the recommended interval may lead to belt fatigue and breakage, which can result in costly engine repairs.

The timing belt is a synchronized transmission belt that transmits power when the belt and pulley establish teeth meshing. The noise level is lower compared to chain and gear and since oiling is not required it is able to achieve clean power transmission.

There are a variety of tooth profiles and size variations for the timing belts. UMS Pty Ltd has a wide Mitsuboshi product availability. These MITSUBOSHI timing belts can be used in place of timing chains as they work in the same way but require less lubrication and make less noise.

Features of OHC Timing Belt

- Stable, high tensile strength synthetic cords resist shrinking and stretching.

- Careful selection of raw materials for excellent durability in high temperatures

- Optimized tooth shape

- High strength timing belt

- Superior transmission efficiency and quietness.

- Constant synchronous power is assured with precision molded teeth that perfectly mesh with pulley grooves pitch, width, and length.

- Special materials assure durability and performance in hot and oily environments.

Benefits

Mitsuboshi Timing Belts offer numerous advantages over chain and gear drives:

- Low noise as compared to metal timing chain

- Reduced weight

- Fuel Savings

- Decreases transmission loss due to high transmission efficiency

- High durability, even in high temperature environment.

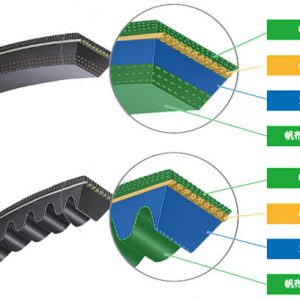

Construction

1. Tensile Cords

High tensile strength fiberglass or aramid cords resist stretching and shrinking.

2. Material

Durability, performance and reliability in tough engine environments.

3. Facing

Wear-resistant fabric protects the tooth surface and keeps friction loss at a minimum.

MITSUBOSHI are original equipment manufacturers and have been supplying all types of Timing Belts for both original equipment and service parts in the automotive and industrial machinery markets. Automotive companies that work closely with Mitsuboshi for their OHC Timing Belt needs are:

CAT, Isuzu, Geo, Opel, Mitsubishi, Peugeot, Saab, Hino, Acura, Daihatsu, Honda, Oldsmobile, Mitsubishi Heavy Duty, UD Trucks (Nissan Diesel), Yanmar Diesel, Fuso, Lincoln, Subaru, Mercury, Kubota, Komatsu, Toyota, Ford, GMC, Suzuki, Chevrolet, Infiniti, Chrysler, Renault, Volvo, Saturn, Porsche, Audi, Nissan, Dodge, Daimler, Cadillac, Buick, Mazda, Lexus, Volkswagen etc.

Industries / Applications

All Giga Torque polyurethane belts are abrasion-resistant, provide thermoplastic flexibility and are long-lasting, energy efficient belts suitable for all heavy-duty industries and applications.

Heavy Duty Truck

Bus

Agricultural

Harvestor

Jeeps

Snowmobile