- Products

- Industries

AUTOMOTIVE

ROAD CONSTRUCTION

AGRICULTURE

FOOD AND BEVERAGES

TRANSPORT & LOGISTICS

AIRCONDITIONING (FANS & COMPRESSORS)

- Contact Us

- RESOURCES

- Blog

Serviwrap cold applied coating designed to provide complete protection against corrosion and electrolysis on below grade metal substrates eqally effective on pipe lengths, bends, joints, fabrications and valves. The anti-corrosion bituminous rubber compound of Serviwrap pipeline protection provides self-sealed joints at longitudinal and end of roll overlaps, and is highly resistant to cathodic elasticity. The unique extruded PVC carrier is engineered for toughness, conformability and controlled elasticity. Serviwrap can be provided in either a Temperate grade or a Tropical grade depending on the application location. Serviwrap consists of a thick layer of self-adhesive compound bonded to a tough flexible outer carrier film.

Features of High-performance Serviwrap PVC – Bitumen pipeline protection tapes:

- Broad range of widths, lengths, and thicknesses to match all pipeline requirements

- Long-term corrosion protection for buried pipelines

- Easy to apply and repair

- Used on a wide range of pipelines, joints, and fittings

- Works in the most challenging natural environments

- A complete system including tapes, primer, and moulding compound.

- Over 30 years of field-proven performance

- Globally recognized as a key corrosion protection solution by major pipeline owners

Uses

RECOMMENDED USE

A high-performance, cold-applied PVC pipe wrap for use on buried and submarine line pipe. For field welds, fabrications, bends and fittings.

SUBSTRATE COMPATIBILITY

Steel, Stainless Steel, Ductile Iron, Other Metals, FBE, PE, Plastic Pipe

VARIOUS TYPES OF SERVIWRAP

Serviwrap R15

It is a 1.14mm thickness, cold-applied coating designed to provide protection against corrosion and electrolysis on below grade metal substrates.

It is a 1.14mm thickness, cold-applied coating designed to provide protection against corrosion and electrolysis on below grade metal substrates.

- A cold-applied PVC pipe wrap for use on small diameter buried pipe with a graded backfill

- For field welds, fabrications bends, and fittings

- Available in Tropical and Temperate grade

Serviwrap T15

It is a 1.14mm thickness, cold-applied coating designed to provide protection against corrosion and electrolysis on below grade metal substrates. Serviwrap T15 is a stiffer tape than the equivalent R15 tape and therefore suitable for machine wrapping applications.

It is a 1.14mm thickness, cold-applied coating designed to provide protection against corrosion and electrolysis on below grade metal substrates. Serviwrap T15 is a stiffer tape than the equivalent R15 tape and therefore suitable for machine wrapping applications.

- A high-performance, cold-applied PVC pipe wrap for use on buried and submarine line pipe

- Also suitable for field welds, fabrications, bends and fittings.

- Available in Tropical and Temperate grade

Serviwrap R30 tape

It is a 1.65mm thickness, cold applied coating.

It is a 1.65mm thickness, cold applied coating.

- A high-performance, cold-applied PVC pipe wrap for use on medium to large diameter buried line pipe

- R30 is a flexible tape system that is suitable for the hand wrapping of field welds, fabrications, bends and fittings

- Available in Tropical and Temperate grade

Serviwrap TB30 tape

It is a premium grade blue filmed 1.65mm thickness, cold applied coating system designed for the machine wrapping of large diameter buried line pipe.

It is a premium grade blue filmed 1.65mm thickness, cold applied coating system designed for the machine wrapping of large diameter buried line pipe.

- Supplied in 60m lengths for machine wrapping

- Suitable for high water table buried applications

- Available in Tropical and Temperate grade

Serviwrap T30 tape

It is a 1.65mm thickness, cold-applied coating designed for predominantly the machine wrapping of larger diameter buried line pipe.

It is a 1.65mm thickness, cold-applied coating designed for predominantly the machine wrapping of larger diameter buried line pipe. - A high-performance, cold-applied PVC pipe wrap for use on buried and submarine line pipe. T30 is a high-performance tape that is suitable for machine and hand wrapping applications

- Available in Tropical and Temperate grade

Serviwrap M30

It is 1.65 mm thickness, cold applied coating designed to provide mechanical and heat protection to subsea pipeline joints which are being filled with marine mastic and foam.

It is 1.65 mm thickness, cold applied coating designed to provide mechanical and heat protection to subsea pipeline joints which are being filled with marine mastic and foam. - For the protection of butt weld joints on concrete weight coated submarine pipelines

Serviwrap Primer AB

Serviwrap requires a primer to allow for permanent adhesion. Serviwrap Primer AB should be applied and allowed to dry prior to application of the tape. See the application guideline for more details. Serviwrap meets all of the performance criteria listed in the most recent revision of: NACE SP0109 (Cold-Applied Laminate Polymeric Tapes). Serviwrap Primer AB is used with all Serviwrap tapes except for M30 and Outerwrap. Primer AB can be used with both Temperate (A) and Tropical (B) tape systems. Primer AB is a quick drying, liquid adhesive that creates a permanent bond between the tape and the substrate. Primer AB can be used for in service temperatures up to 75°C. Primer AB is available as a liquid that is applied via brush, roller or spray equipment. A 25-50 micron wet film thickness of Primer AB should be applied and allowed to dry prior to application of the tape.

SURFACE PREPARATION

The surface to be wrapped should be as clean as possible. Remove metal burrs and other projections, and all loose matter, any existing coatings, dirt, rust and foreign debris. Ensure all oil and grease is removed with solvent. Inspect old pipework or factory coatings and remove any loose coating back to sound material with wire brushing. Where new or existing steelwork has been subjected to chemical attack, salt spray, fungi or bacteria other methods may be used.

Industries / Applications

A wide range of machinery from light duty power transmission for OA and household electric appliances to heavy duty power transmission such as printing machines, machine tools and crushers

Industrial Power Transmission

Agricultural

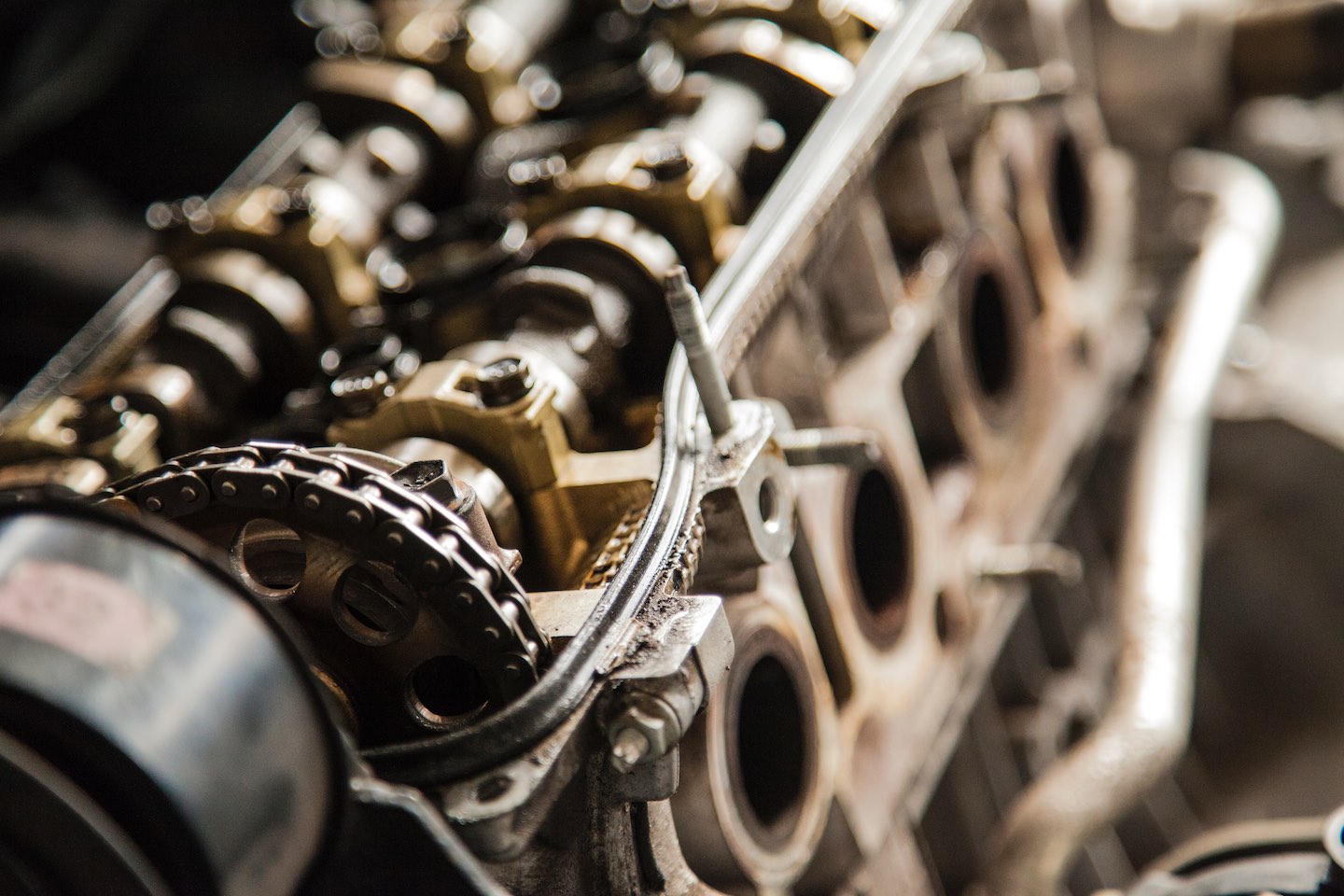

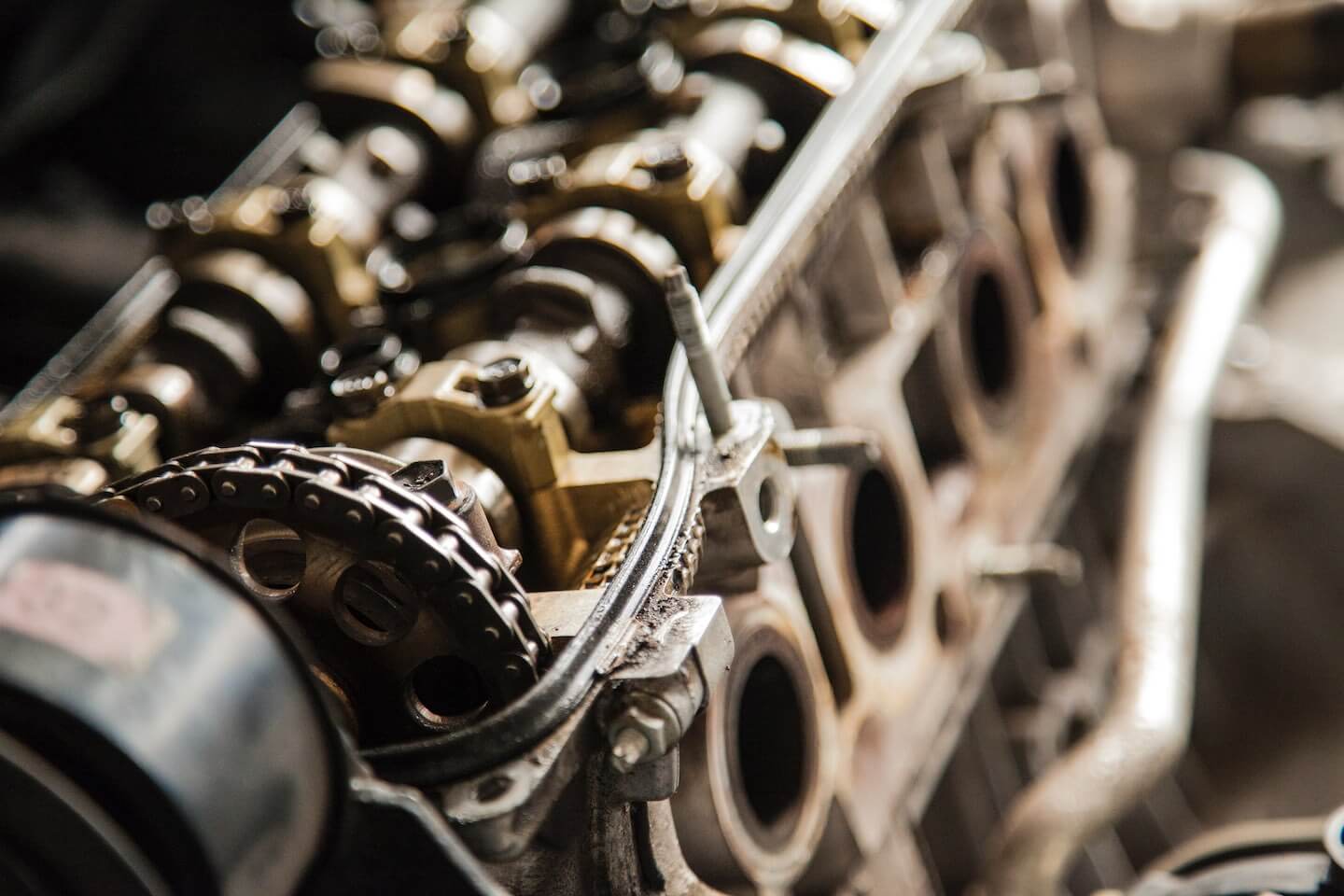

Automotive

Pipeline Protection for Oil & Gas, Waterworks

Food Industry Conveyor Belts

Paver Belt